Introduction to K24 Propane Idle Air Shutoff Valve

The K24 Propane Idle Air Shutoff Valve is vital in various propane-powered structures, ensuring the safe and efficient operation of engines and other equipment. This valve is designed to routinely regulate propane flow when the engine is idling or in low-consumption situations, stopping wasteful fuel consumption and reducing emissions. This comprehensive guide delves into the information about the K24 Propane Idle Shutoff Valve, discussing its features, characteristics, programs, setup processes, protection essentials, and troubleshooting techniques.

Understanding the role of shutoff valves at idle

K24 Propane Idle Air Shutoff Valve are vital to propane-fueled engines and structures, especially in applications where the engine may additionally spend long periods idle. These valves are designed to automatically shut off the propane flow when the engine is idling, preventing wasted gas and ensuring the engine runs efficiently. Using an idle shutoff also contributes to environmental protection by reducing unburned hydrocarbon emissions when the engine requires low fuel consumption.

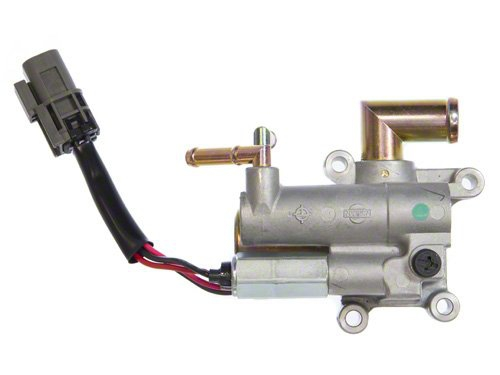

Overview of the K24 Propane Idle Air Shutoff Valve

The K24 Propane Idle Air Shutoff Valve is a specialized tool for reliability and durability in harsh environments. It precisely varies the propane flow and automatically shuts off the fuel supply when the engine is idling. This feature is particularly useful in applications where gas performance and emissions are critical, such as commercial engines, industrial equipment, and power backup mills. The K24 valve is built to stand the test of continuous use, making it a popular choice for professionals who demand reliable performance.

Key Features of the K24 Propane Idle Air Shutoff Valve

The K24 Propane Idle Air Shutoff Valve is outstanding, with several key features that enhance its overall performance and reliability. One of the coolest features is its specific control mechanism that ensures the valve responds precisely to changes in engine demand. This accuracy is critical to maintaining maximum fuel performance and reducing emissions. The valve is also designed to be robust, with fantastic materials that resist corrosion and set, ensuring the provider’s prolonged existence even in demanding situations. In addition, the K24 valve has built-in safety features that save you gas leaks and protect the engine from potential damage.

Application of the K24 Propane Idle Air Shutoff Valve

The versatility of the K24 Propane Idle Air Shutoff Valve makes it suitable for a wide variety of packages. In the automotive industry, the valve is commonly used in propane-powered vehicles such as forklifts, commercial vehicles, and buses, and it helps reduce gasoline consumption and emissions during idle intervals. In an industrial environment, the K24 valve is used in equipment with turbines, compressors, and other devices that work intermittently or in various hundreds. The valve’s ability to automatically adjust gas flow primarily based on engine requirements makes it strongly preferred for designs where efficiency and environmental compliance are a priority.

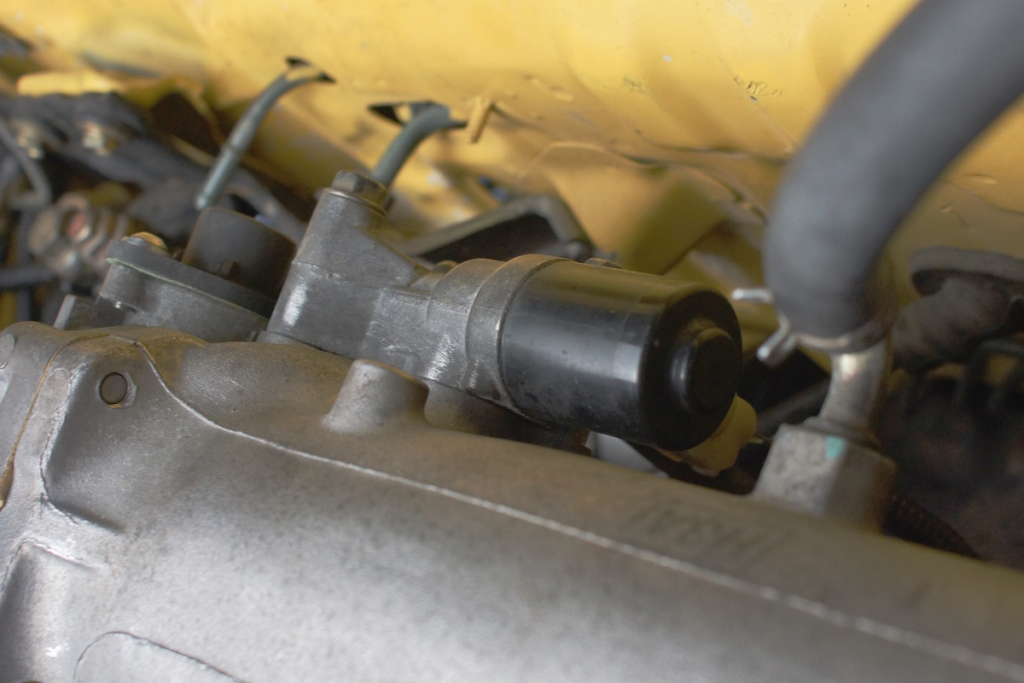

K24 Propane Idle Air Shutoff Valve Installation

Proper adjustment of the K24 Propane Idle Air Shutoff Valve is important to ensure its accurate function and durability. The installation technique begins with choosing the best location for the valve, usually near the fuel supply line and close to the engine. The valve must be set securely to minimize vibration and ensure strong operation. Once in the vicinity, the valve is remotely connected to the propane supply line and engine intake using appropriate fittings. It is important to ensure that each connection is tight and stable to prevent leaks. After installation, the machine should be tested to confirm that the valve works effectively by closing the gas supply during idle and opening it again while the engine demand increases.

K24 Propane Idle Air Shutoff Valve Maintenance

Regular maintenance is important to keep the K24 Propane Idle Air Shutoff Valve in top operating condition. Maintenance duties include checking the valve and associated components for signs of damage or corrosion and cleaning the valve to remove any dirt or deposits that could affect its overall performance. It is also important to regularly test the valve’s response to changes in engine demand and ensure that it shuts off and reopens the fuel supply as needed. If any problems are found, including leaks or delayed response, the valve must be repaired or replaced immediately to prevent further problems.

Troubleshooting common problems

Despite its robust construction, the K24 Propane Idle Air Shutoff Valve can occasionally run into problems that require troubleshooting. One common problem is a failure of the valve to shut off the fuel supply during idle, which could cause increased gasoline intake and emissions. A malfunctioning control mechanism or a blocked valve can cause these problems. Analyzing and cleaning the valve can solve the problem and test the devices in such cases. The other problem is valve failure when reopening the fuel supply when the engine requires a boost, which can cause engine stalling or poor overall performance. This problem may be related to a faulty sensor or actuator that requires replacement of the affected components.

Benefits of using the K24 Propane Idle Air Shutoff Valve

The K24 Propane Idle Air Shutoff Valve provides several significant benefits, making it a valuable addition to propane-powered systems. One of the main benefits is its ability to beautify gasoline efficiency by robotically shutting down the propane supply during idle periods, reducing fuel consumption and operating costs. The valve also contributes to environmental protection by minimizing emissions of unburned hydrocarbons; the supporting structures meet strict emission regulations. In addition, the K24 valve’s long-lasting design and reliable performance ensure long-term operation with minimal maintenance, giving customers peace of mind and reducing the need for frequent replacements.

Comparison of the K24 Propane Idle Air Shutoff Valve with other valves

In the idle Shutoff market, the K24 idle Shutoff features a blend of precision, durability, and flexibility. Compared to different valves, the K24 provides advanced control over propane flow, ensuring fuel delivery is controlled efficiently even in variable situations. While other valves may offer similar primary features, strong manufacturing and excellent safety features set them apart, making them a reliable choice for stressful programs. In addition, the compatibility of the K24 valve with many engines and systems adds to its appeal to customers in various industries.

Environmental Impact and K24 Propane Idle ShutShutoffve

As environmental concerns influence the design and operation of commercial and industrial systems, the K24 Propane Idle ShutShutoffve plays a vital role in reducing the environmental impact of propane-powered engines. By ensuring the correct control of the gas supply, the valve reduces the machine’s e’s overall carbon footprint and the emission of hazardous pollutants. This is particularly important in industries where legal compliance with environmental protection requirements is mandatory. The K24 valve now supports these compliance efforts and contributes to broader sustainability requirements by promoting energy efficiency and reducing resource consumption.

Future developments in idle Shutoff technology

The idle stop valve era field is poised for major improvements as new materials, control systems, and environmental requirements emerge. Future trends could also include integrating digital sensors and smart generation into K24 Propane Idle Air Shutoff Valve, allowing for better specific control and monitoring of fuel timing in line with flow. These improvements can lead to even greater fuel efficiency and emissions reductions and advanced diagnostic skills to identify and resolve problems before they affect system performance. Additionally, as the use of alternative fuels increases along with renewable propane, idle Shutoff will want to adapt to ensure compatibility and the most desired performance with these new energy sources.

The role of the K24 propane idle Shutoff in emissions control

In a new world where environmental regulations are becoming more stringent, controlling emissions from propane-powered engines is more important than ever. The K24 propane idle shutoff plays a vital role in this regard, helping to minimize the release of unburned hydrocarbons, especially during idle intervals. When the engine is idling, it uses fuel without doing much work, which could lead to better emissions if not managed well now. The K24 valve solves this problem by shutting off the propane supply when the engine is not under load, stopping the unnecessary release of pollutants into the atmosphere.

This property is especially crucial in urban areas and other environments where pleasant air quality is a major problem. By using the K24 valve, operators can ensure that their engines comply with ambient emissions requirements, reducing their environmental impact and contributing to cleaner air. In addition, reduced emissions help extend the lifestyle of catalytic converters and various emission control devices that can be damaged by excessive hydrocarbon build-up.

Integrating the K24 Propane Idle Air Shutoff Valve with modern engine management systems

As engine generations progress, combining additives such as the K24 Propane Idle Shutoff with modern engine control structures becomes increasingly important. Engine control structures that use sensors and microprocessors to control various elements of engine operation can benefit significantly from including an idle Shutoff. The K24 valve can be interfaced with these structures to provide real-time control of gasoline delivery, improving overall engine efficiency and performance.

This integration allows for extra precise adjustments based entirely on engine load, speed, and various elements, ensuring that propane delivery is always optimally controlled. For example, in a fleet of industrial vehicles, using a K24 valve on the side of a sophisticated engine control machine can bring great financial savings in fuel and reduce emissions, especially lower operating costs, and a smaller environmental footprint. As the demand for smarter, more efficient engines grows, the function of the K24 valve in these systems is likely to grow even more.

Economic Benefits of the K24 Propane Idle Air Shutoff Valve

In addition to its environmental blessings, the K24 Propane Idle Shutoff provides tremendous financial benefits to customers. By reducing fuel consumption during idling, the valve helps reduce operating costs, especially in generator sets where the engines spend a lot of time idling. This is especially true in sectors such as transport, where gas expenses represent a major part of current charges.

Challenges and Considerations in Using the K24 Propane Idle Air Shutoff Valve the K24 Propane Idle Shutoff offoff offers several benefits. Still, there are also challenges and issues that users must consider. The most challenging situation is ensuring the valve is calibrated and incorporated into current engine systems. Improper calibration or improper installation can cause problems with a delayed response, improper gas shutoff, or a cut of engine stalling. That’s why it’s important to follow the manufacturer’s instructions carefully and, if important, talk to a professional plumber to ensure the valve is set correctly.

Future Prospects for the K24 Propane Idle SShutoff The future of the K24 propane idle sshutoff looks promising as gas efficiency and emission reduction requirements evolve. Innovations in technological know-how in materials, handling systems, and sensor technology are likely to lead to even more advanced versions of the K24 valve, featuring desirable overall performance and greater adaptability to different engine types and operating environments.

Conclusion: The K24 Propane Idle Shutoff is a key component of modern propane systems

The K24 Propane Idle Shutoff is critical for optimizing the overall performance of propane-fueled systems. Its ability to rout environmental propane flow under all idle conditions makes it a rare gas intake and emissions reduction device. However, its long-life design ensures long-term reliability even in worrisome packages. Whether used in automobiles, industrial equipment, or backup power structures, the K24 valve gives users confidence that their engines will perform accurately and successfully in all situations.